clean water

protecting the water

oil spill prevention and response

The success of our oil spill prevention efforts is demonstrated in the very low incident record at the El Segundo Refinery Marine Terminal. Our Marine Terminal is state of the art with measures in place built into our standard operating procedures to prevent oil reaching the Santa Monica Bay. A few examples are 60 second valves and a continuous vacuum system for the submarine lines when not transferring product.

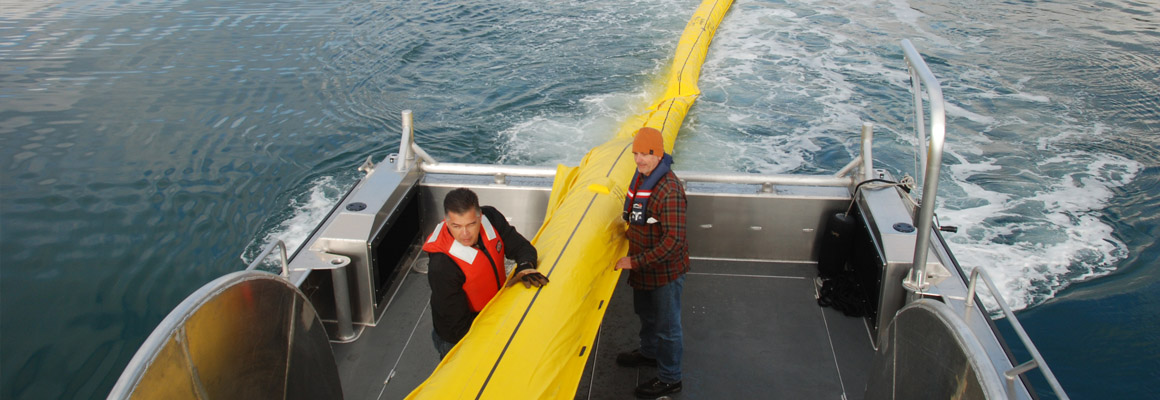

In addition to our prevention measures, we have a well-trained Oil Spill Response Team comprised of over 110 volunteer employees who respond in the event of an oil spill. Throughout the year, these employees, from all areas and job functions in the refinery, work closely with Local, State and Federal agencies to train on our response vessels deploying boom and on our Response Plan protecting the environment.

Representatives from the team participate in the advisory meetings of our local Oil Spill Response Organization and in the USCG/OSPR Area Committee meetings. Working with the USCG, Department of Fish & Wildlife OSPR and with our OSRO’s, we remain up to date on all regulatory changes and new technologies available in the field of oil spill prevention and response.

groundwater protection

We have been very successful in cleaning the groundwater beneath the El Segundo Refinery. Our extensive number of recovery wells has virtually eliminated hydrocarbon vapors in El Segundo and Manhattan Beach. To protect the groundwater, the majority of tanks in the refinery that hold petroleum products have been fitted with double bottoms and leak detection systems. Chevron was the first in the U.S. to adopt a standard for double bottoms on our tanks. In addition, we developed the technology for secondary containment with leak detection.

We have over 1,100 miles of pipeline in this facility, most of which used to be buried. Using what we call the “daylighting” process, the pipes have been moved above ground so, in case of a leak, it can be more easily detected. The “sleeving” process, where one pipe is inserted into another pipe, is an additional method we use in order to catch and prevent any leaks.