air quality

reducing air emissions

reformulated fuel

cogeneration facilities

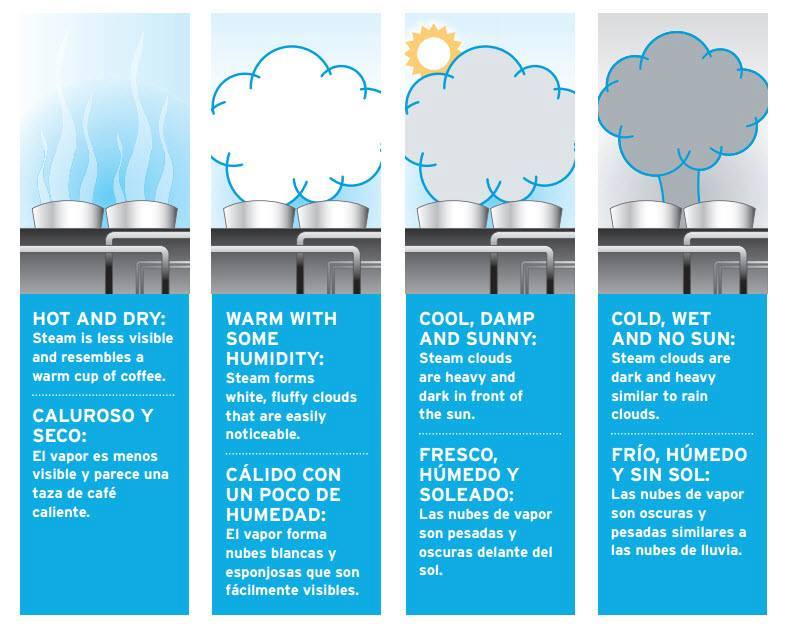

steam

safety flares

A flare is a safety device used to eliminate excess pressure buildup in the refinery. Whenever pressure in the plant begins to rise, the material is safely diverted to a relief system where it is burned in smokeless flares. These flares turn hydrocarbon vapors into harmless water vapor and carbon dioxide. Flares are designed for this process, so there is no need to be alarmed when you see them doing their job.

Occasionally, you may see smoke coming from the flares. This may happen during an unplanned shutdown when steam cannot be added to the system quickly enough to eliminate smoking. Fortunately, these events are infrequent and are usually of short duration.

If you have any questions during a flaring event, please call our 24-Hour Community Hotline at 310.615.5342.